- Electrical Contact

- Tungsten Rod

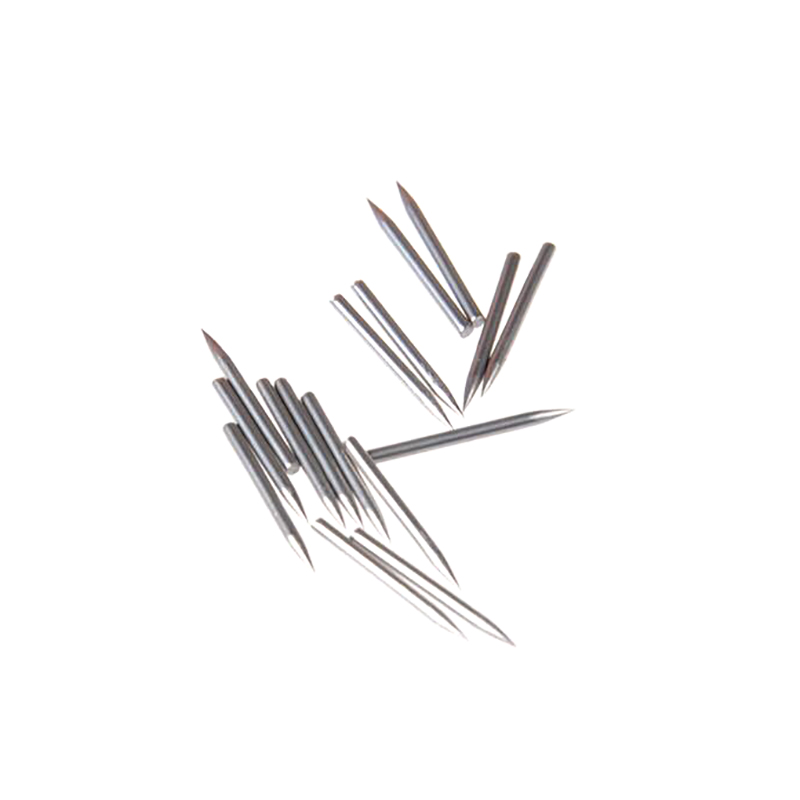

- Tungsten Needle

- Tungsten Particles

- Tungsten Electrode

- Tungsten Spheres/Tungsten Ball

- Solid Molybdenum Wire

- Special Shaped Molybdenum Electrode

- High Temperature Resistant Special-Shaped Molybdenum Screw

- Rivet

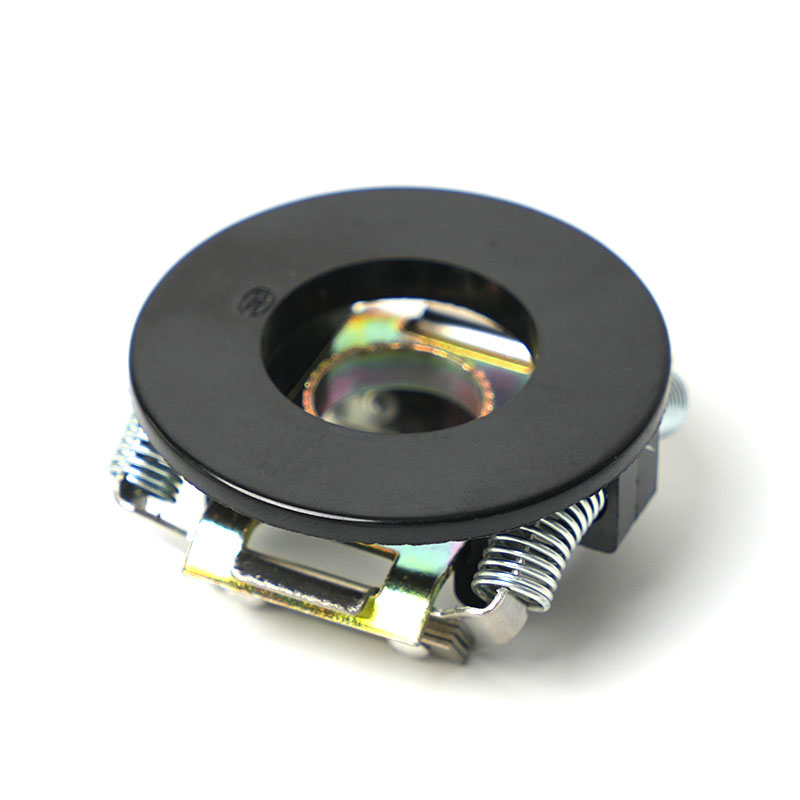

- Single-Phase Motor Centrifugal Switch

- Tungsten Disc/Tungsten Plate

Need help? Call us:

+86-513-87832313

or

ygr13906273952@163.com

Argon Arc Welding Round Tungsten Needle suppliers

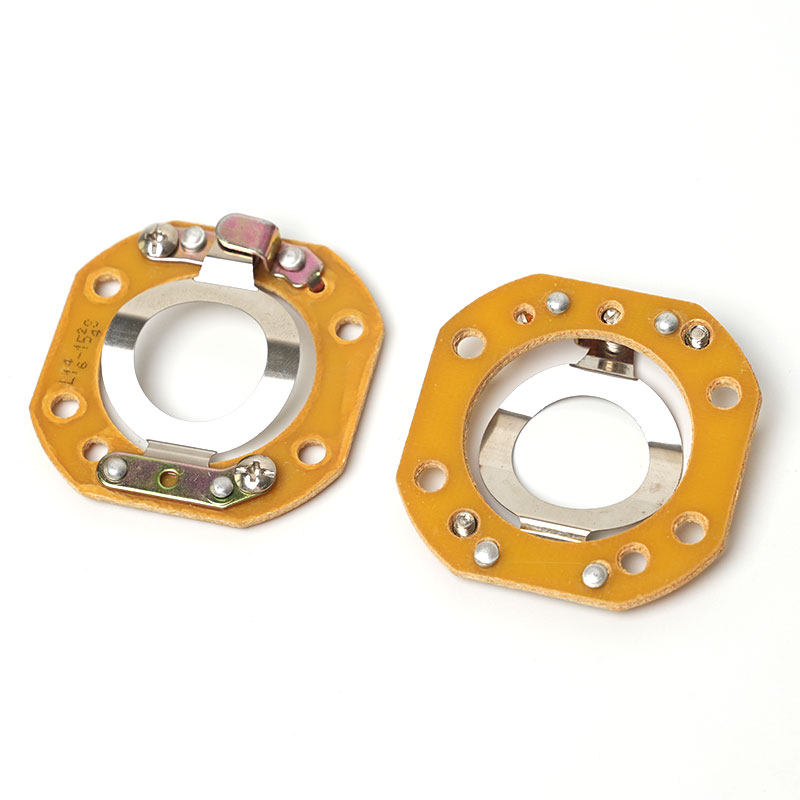

Electrical Contact

Tungsten Bimetal Contact Point For Automotive Horn

High Temperature Resistant Automotive Horn Tungsten Contacts

Iron-Tungsten Contacts For Circuit Breakers, Contactors

High Temperature Resistant Switch Electrical Contact

High Power Bimetallic Rivets Electrical Tungsten Contact Relay Switch

Round Tungsten Copper Arc Contact

Wear-Resistant Tungsten Copper Electrical Spring Contacts

Low Contact Resistance Iron-Tungsten Electrical Contacts

Highly Conductive Silver Copper Electrical Contacts

Bimetallic Rivets Silver Copper Contacts For Electrical Switches

Tungsten Rod

Tig Welding Electrode Material Tungsten Welding Rod

3MM 4MM 6MM 8MM 10MM 12MM Tungsten Carbide Rod/Tungsten Bar For Metal Processing

Tungsten Needle

Round Rod Sharpening Wear-Resistance Cemented Carbide Tungsten Needles

Argon Arc Welding Round Tungsten Needle

Negative Ion Discharge Pointed Tungsten Carbide Needle

Medical Pointed Tip Tungsten Carbide Needle

Tungsten electrode discharge needle

Silicon Needle

Tungsten Particles

High Purity Tungsten Particles Tungsten Carbide Powder

Tungsten Granules/Metal Tungsten Particle Flux

Tungsten Electrode

Industrial TIG Welding Tungsten Electrode

Sharpening Tungsten Electrode For Stainless Steel/Aluminum Welding

Tungsten Spheres/Tungsten Ball

High Precision 99% Pure Tungsten Spheres Polished Tungsten Ball

Tungsten Carbide Alloy Bearing Balls

Solid Molybdenum Wire

Solid Molybdenum Cutting Wire

High-Temperature Furnace Heating Element Molybdenum Wire

Special Shaped Molybdenum Electrode

Polishing Corrosion Resistant Molybdenum Electrode

Special Shaped Molybdenum Electrode For Glass Melting Furnace

High Temperature Resistant Special-Shaped Molybdenum Screw

Special-Shaped Molybdenum Screw For High Temperature Furnaces

High Temperature Special-Shaped High Density Pure Molybdenum Screws

English

English

中文简体

中文简体